Cladding

Weld cladding as

material & surface protection

For components in

‘ Waste incineration plants

‘ Biomass plants

‘ Coal and gas boilers

‘ Fluidized bed boilers

‘ Chemical plants

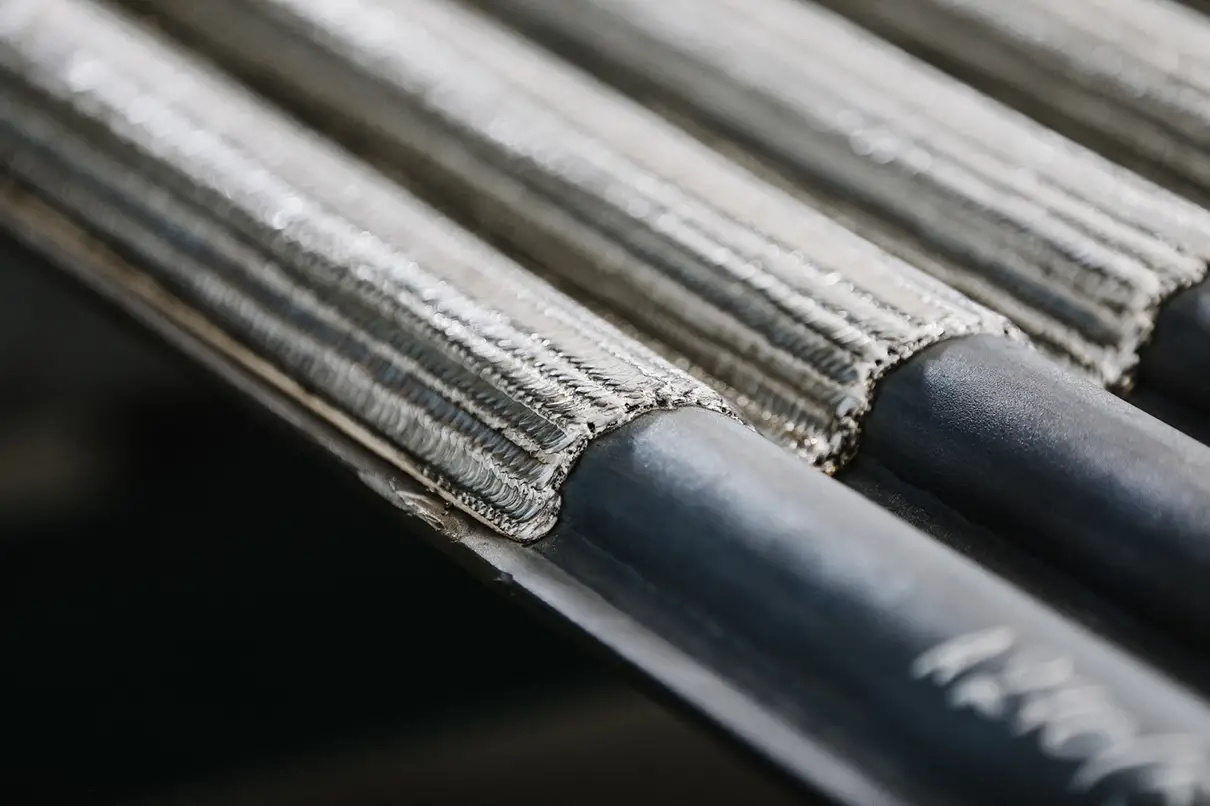

Ni-based weld cladding against corrosion:

‘ Alloy 622

‘ Alloy 625

‘ Alloy 59

‘ Alloy 686

Weld cladding against erosion

‘ Use of welding consumables with high Cr content and similar materials

Weld cladding of

single pipes (single pipe cladding)

‘ Circumferential cladding / spiral cladding of headers & individual pipes (e.g. for superheater packages)

‘ Cladding lengths: max. 14 meters per pipe

‘ Layer thicknesses: 1mm to ≥2mm

‘ Welding process: E-pulse or CMT process (cold metal transfer)

Weld cladding of

Membrane walls

(membrane wall cladding)

‘ Production of ready-to-install membrane wall panels (tube-web-tube)

‘ Layer thicknesses: >1mm to ≥2mm

‘ Cladding lengths: max. 9 m per panel

‘ Welding process: Two-layer CMT technique with 50% overlap

Construction site cladding

‘ Maintaining the availability and efficiency of the systems

‘ Weld cladding directly on site for zones particularly at risk of erosion/corrosion

‘ Initial cladding as a preventive measure

‘ Repair & Re-Cladding

‘ Cladding with automatic welding machines / cladding by hand (all welding positions possible)

‘ Work in several shifts possible, including weekends